Pressure Treated Wood Fence

In 2004, the EPA banned the use of Chromate Copper Arsenate (CCA) as an outdoor lumber preservative for residential applications. The Lumber preservative changed to Alkaline Copper Quaternary (ACQ). It failed miserably. Then came Micronized Copper Azole (MCA) and EcoLife (E2) in late 2007. Followed by Copper Azole (CA), and Then Copper Azole Type C (CA-C) in 2009. As of current, there are15 different chemicals endorsed by the American Wood Protection Association. Each of those chemicals falls under 12 end-use categories. The question is which pressure-treating chemical is right for your fence.

The problem is the home improvement stores and lumberyards sell all of them, but here in Central Florida, you're only interested in three. Use lumber treated with the wrong chemical or inadequate building method and you're asking for trouble. Simply put, trust those so one who does not know what they are doing, and your fence will be destroyed within three to five years. It is your wallet.

As the owner of Paramount Fencing, I understand the importance of using the correct pressure-treating chemicals.

Let's start with the basics. Pressure-treated lumber refers to the process of infusing a chemical-based solution deep into or completely through a piece of wood. Treatment is accomplished by placing wood in a large chamber, filling it with liquid solutions, and pressurizing the chamber once the lumber is saturated. As a result, the chemicals will prevent or block the wood fibers from becoming a food source for termites and fungal decay: It's that simple.

What is not simple is understanding how these chemicals base solutions protect the wood. Let break it down. A preventive based chemical treatment simply exists within the lumber and a blocker adheres to the wood fibers within the lumber. Understand, a preventive base solution only works so long as it remains within the lumber.

The problem in Central Florida is pressure-treated wood fences are constantly assaulted by groundwater, rainfall, and irrigation systems. Like a sponge, the wood absorbs the water and the lumber swells. Unlike a sponge, that lumber cannot be rung out. So the abundance of water slowly forces the very chemicals meant to protect it out: AKA Leaching. A blocker based treatment, on the other hand, allows the compounds of the chemical to sticks to the wood fibers resulting in better retention. Simply put, the treatment lasts longer.

Preventive base treatment such as MCA and E2 were the treatment of choice for all outdoor lumber from 2007 to 2011. It did not matter if the end-use was above or below ground. In 2009, the makers of the chemical MCA started to realize lumber placed below or in contact with the ground was rotting. E2, on the other hand, possessed wood polymers and stabilizers whose sole function was to delay water absorbing for 1-3 years. In 2011, the pressure-treating industry realized there was a systemic problem. Bottom line, both MCA and E2 treated lumbers was rotting when within 6" of the ground.

So began the race to find the cure for fungal decay and rotting at ground level. The two major chemical producers of chemical-based treated solutions, Viance and Osmosis, created two different new treatment code Copper Azole Type C (CA-C) and MCA-C. Then began the battle for control of the American Wood Protection Association (AWPA) classification codes and standards. Both companies slugged it out. Both approaches were not created equal. To avoid market confusion, the AWPA introduced three new end-use categories for pressure-treating lumber in their 2016 standards: UC4A, UC4B, and UC4C.

AWPA was based on the fact lumber is treated it is treated for a particular end-use application with different chemicals. Now, depending on the end-use, the retention percentage of the chemical-based solution within the lumber determined how effective the chemical would be given in a certain condition. Case in point, the category UC4a is meant for ground contact (general use), within an environment that promotes rapid watershed were as UC4B is meant for ground contact (heavy duty) within an environment that possesses slow watershed. Finally, UC4C is meant for ground contact (extreme duty) within an environment consisting of stagnating water.

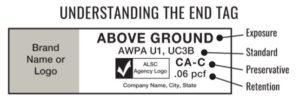

As you can see, knowing is half the battle. So the question is, how do you know you're purchasing the right pressure-treated lumber or is that fence company installing the correct stuff?  It simple, look no further than the tag stapled to the piece of lumber. If you need further explanation or a better understanding of what category and chemical are right for each building situation, print off the AWPA's pamphlet. or click on the link. Then as the old saying goes, "Trust but Verify." Take it with you to the home improvement store or better yet take a tag off the lumber being used to install your fence.

It simple, look no further than the tag stapled to the piece of lumber. If you need further explanation or a better understanding of what category and chemical are right for each building situation, print off the AWPA's pamphlet. or click on the link. Then as the old saying goes, "Trust but Verify." Take it with you to the home improvement store or better yet take a tag off the lumber being used to install your fence.

We cannot stress this enough: It is now more important than ever to understand the intricacies of pressure-treated lumber and the manner in which your wood fence is constructed. No none of our competitors will share this information with you, and some will say, "We are crazy." But just look around your neighborhood and chances are you will see rotting pickets and posts hard at work.

What Is Right Combination Pressure Treatment Lumber for Central Florida?

The key to understanding three basic components of a wood fence and what it's exposed to after installation: (1) Post, (2) Runners, and (3) Pickets.

(1) Posts:

Posts are the vertical supports and 1/3 of that post is generally buried in the ground. As a result, all posts in the state of Florida should be treated with CA-C or CA and be classified in the UC4B category, ground contact, heavy-duty. If your property possesses standing water for more then 1 week at a time or is gushy when walking on it, UC4C, ground contact, extreme duty, should be the desired choice. The reason is simple. The State of Florida receives on average 57" of annual precipitation during the rainy season alone. The Orlando area 52". Next, our water table is often less than 4-6 feet below your feet. When the dry season arrives, the homeowner's irrigation system comes on. Remember that wood acts like a sponge and absorbs water, and when it does, the treatment slow seep out. Understand, should you use a post-treated with UC4A it must possess some type of Post Saver Technology protecting it at grade. Otherwise, a post-treated with UC4A will rot off at grade within 8-11 years.

Now, chances are no home improvement store or lumber yard will readily stock UC4B or UC4C treated posts. More likely than not these classification will need to be special ordered. Most stock UC4A, but post saver technology must be accounted for.

(2) Runners:

Horizontal Runners are the backbone of a fence. It all starts with the framework. There are two simple rules of thumb. First, it's important to ensure there are (3) horizontal runners on any six foot in height fence. Each treated with treated with a minimum of UC3B chemical class; however, before ward this classification treated-lumber must be installed a minimum of six inches off the ground. Two, when in doubt switch it out. If you know that bottom runner of that new fence is going violate the 6" rule, switch it out ot a UC4A class.

(3) Pickets:

Pickets are the what provide privacy and security. I one simple rule. Regardless of the pressure-treated chemical used, it must be rated in the UC4A class and tagged meant for ground contact. Be forward, if you have a soggy yard, the classification should be rated for a UC4B class.

For more information feel free to visit Paramount Fencing, wood buying fence guide.

We cannot stress this enough: It is now more important than ever to understand the intricacies of pressure-treated lumber and how your new wood fence is going to be constructed. None of our competitors will share this information with you, and some will say, "We are crazy." But just look around your neighborhood and chances are you will see rotting pickets and post hard at work.

So don't be the homeowner that gets mesmerized by the likable salesperson or discount fence company. If you do and use the wrong fasteners and pressure treating code, the pickets will separate from the runners within 12 months, the framework will separate from the posts within 36 months, and that beautiful fence will warp itself apart and those pickets will rot within 5-8 years. Simply put, that new wood fence will become nothing more than a Popsicle stick experiment.

These are real problems that can occur with a pressure-treated wood fence but do not get discouraged. These problems are preventable.

These are real problems that can occur with a pressure-treated wood fence but do not get discouraged. These problems are preventable.

We cannot stress this enough: It is now more important than ever to understand the intricacies of pressure-treated lumber and how your wood fence is going to be constructed wood fence is constructed. We highly recommend that the homeowner read our comprehensive guide to purchasing wood fences before scheduling a single estimate.

These issues are correctable if the fence is built properly. The good news is we conduct testing every year and our building methods have been designed to counter these distinct problems and ensure that wood is still a viable option that can last 18 - 20 years.

So take the time to educate yourself, and don't become the victim. Remember, as the old saying goes, "An ounce of prevention is worth a pound of cure."

Paramount Fencing is currently customizing wood fences in the following Orange & Seminole County Cities: Waterford, Windermere, Oviedo, Orlando, Winter Springs, Lake Mary, Sanford, Winter Garden, Ocoee, St. Cloud, Winter Park, Casselberry, College Park, Clermont, Maitland, Longwood.