A wood fence is a wood fence, right? Nope. If you are considering a wood fence, you will soon discover, after gathering estimates, how confusing the wood fence market has become as of late.

Complicating the already complicated, new fence companies and products are popping up monthly as the economy rebounds. Each new company brings with them their own standards and opinions and their own methods and marketing strategies. As a result, it can be difficult to separate fact from fiction; however, as in life, the answers will be found through research.

The Comprehensive Wood Guide is an educational tool which is designed as a resource for both consumers and competitors alike. The guide is based on scientific research, independent sources, and field experiments and findings.

Last-if you have any suggestions or have a question, please email us at general@paramountfencing.com. We will will make sure your question is answered and placed within the guide.

Happy Reading.

FACTOR ONE: WOOD SELECTION

In the Central Florida Market, there are two prominent types of wood used to construct wood fences: (1) Pressure Treated Pine or (2) Cypress. At times, a combination of both types of lumber are used. For example, one fence company might build using all pressure treated and another might build using (PT) framework and cypress pickets.

So which wood is better, pressure treated pine or cypress? That is the question at hand. There is no simple answer, only a long explanation with variables such as where the tree was harvested from, it's age, the manner in which it was milled, and its use in the marketplace.

When comes to fencing, both cypress and pressure treated pine have similar, if not equal, benefits; however, if used incorrectly, both types of wood will reap any substantial return on investment. The best place to understand begins at the heart the matter--the tree from which the wood was harvested.

In this section, the information provided will focus first on the tree species and establish a baseline understanding, such as what make tree function in the natural environment and the attributes which remain once harvested and milled. Along the way, field study will provide real time data. As always, it is important to understand the environmental impacts that are associated with harvesting of trees to their final resting place, the fence line.

We will examine Bald-Cypress first and Then Pressure Treated Pine. By the end, you will know enough to make a well-informed decision:

Bald-cypress: Taxodium Distichum

The most common cypress tree harvested and mill for use of fence construction is the Bald-cypress tree: AKA Gulf cypress, red cypress, southern cypress, swamp cypress, white cypress and yellow cypress.

Bald-Cypress is a slow growing, long living tree, which can reach height of 100 - 125 feet. Bald-cypress exists mainly, "...along the Atlantic Coastal Plain from southern Delaware to southern Florida, westward along the lower Gulf Coast Plain to southeastern Texas.” In the natural forest, a Bald cypress can take upwards of 200 years to develop a significant about of heartwood which is necessary for high lumber-yields.

True stability, strength, and resistance against insects and disease does not occur until a Bald-Cypress reaches an average age of seventy-five or has a growth ring count per inch of 15-20. The main reason is after 75 a chemical called Cypressene is produced as a result of sufficient amount of heartwood.

Traditionally speaking, Bald cypress provides a natural level of protection against decay and insects once harvested, were as pine must be pressure treated to achieve the same level of protection. However, there is an ongoing debate and concern, within the industry, that 2nd-growth cypress does not provide the same benefits as 1st-growth cypress.

The debate revolves around three issues: (1) The tree growth-ring count, (2) Cypressene Oil, and (3) The maturity of the tree itself.

To understand what is causing the debate, it is important to examine what make bald cypress so effective. As a bald cypress tree matures, the growth-rings become closer and closer. When the rings become tighter and closer together, heartwood is created and an oil called Cypressene is abundantly produced, protecting the tree from insects and disease. True stability, strength, and resistance does not occur until a tree growth ring count becomes 15-50 per inch which normally does not occur until the tree reaches an average age of seventy five. In contrast, the maturity old growth has minimum 24-80 growth rings per inch.

In today's market, cypress lumber with high growth ring counts exceeding 20 per inch is associated with reclaimed cypress (also known as sinker cypress) that sunk to the bottom of the river during transport in the early 1900's. Sinker Cypress is very, very expensive. The cypress trees harvested today for fence pickets will have less than fifteen growth rings per inch, hence the debate. Is there protection or not?

Based on in-house study and research reports, cypress provides the best protection against insects and decay when the lumbers dimensions reach 1" or greater. The contributing findings were based on two factors: Thicker Lumber is milled from more mature trees with a growth ring count of a minimum of 10 per inch or greater. See full studies and photos.

It should also be noted in the study, there was no distinct advantage discovered which would suggest that the commonly used 1/2" cypress pickets possess an longevity advantage, against fungal decay and bugs, over the commonly used 5/8" pressure treated pine picket. See full studies and photos.

Milling Method:

Once the bald cypress is harvested, the tree is sent to a sawmill where it is cut in dimensional lumber after air drying or is kiln dried prior to milling dimensional lumber. If the tree is air dried, it is call Green Cypress. If the tree is dried in a kiln it is known as Kiln Dried Cypress.

Green Cypress: Cypress that is air dry naturally by air with a moisture content of 65% remaining in the tree prior to milling.

Kiln Dried Cypress: Cypress is placed in large kilns which reduces the moisture content remaining in the tree to a range of 12% -18%

The kiln dried method has an advantage over green cypress. The main reason is the moisture is removed from the tree in a slow and controlled environment, which minimizes the shrinkage and structural damage to the cells within the lumber. Green cypress on the other hand is milled while the tree is still highly saturated. Once milled, the board rapidly loses moisture content. As a result, damage can occur to the cells of the fiber causing massive shrinkage of board sizes and splitting.

Most fence boards or pickets used within the Central Florida market are green cypress.

Ecological Impact:

In a recent study conducted by a commission established by the Governor of Louisiana in 2005, (C-P and ULCWF), it was discovered that the re-growth rate of Bald and Tupelo Cypress in areas where heavily harvested is not regenerating consistently or at all. The lack of regeneration is contributed to the disruption of water levels, which do not allow the cypress seed with a cone to properly germinate. Other factors include the lack of wildlife once the area is harvested. Certain species such as waterfowl, rabbits, squirrels, even reptiles are forced from the area. As a result, the animals that naturally eat the seeds and disperse them are absent.

It has also been noted that cypress forests serve a purpose of acting like a buffer for heavy coastal winds and tidal surges, often holding excess floodwaters and helping to protect coastal towns from tropical storms and hurricanes. Wetlands are also especially good at cleaning water. Cypress trees and other plants found in these marshy areas filter the water, removing excess nutrients and toxins. The wetlands also house many aquatic species, such as mosquitofish, gar, and many species of snails that help in breaking down and filtering human sewage, toxic metals, and other pollutants from the water.

Resources used for this section:

Texas Parks and Wildlife

United States Department of Agriculture NRCS

University of Florida IFAS Extension

Conservation, Protection and Utilization of Louisiana’s Coastal Wetland Forests: Commission report

Cypress Wood Lumber

Cypress Crack Sawmill

FACTOR TWO: PRESSURE TREATING CODE

In 2004, the EPA banned the use of Chromate Copper Arsenate (CCA) as an outdoor lumber preservative for residential applications. The Lumber preservative changed to Alkaline Copper Quaternary (ACQ). It failed miserably. Then came Micronized Copper Azole (MCA) and EcoLife (E2) in late 2007. Followed by Copper Azole (CA), and Then Copper Azole Type C (CA-C) in 2009. As of current, there are 15 different chemicals endorsed by the American Wood Protection Association. Each of those chemicals falls under 12 end-use categories. The question is which pressure-treating chemical is right for your fence.

The problem is the home improvement stores and lumberyards sell all of them, but here in Central Florida, you're only interested in three. Use lumber treated with the wrong chemical or inadequate building method and you're asking for trouble. Simply put, trust those who do not know what they are doing, and your fence will be destroyed within three to five years.

Let's start with the basics. Pressure-treated lumber refers to the process of infusing a chemical-based solution deep into or completely through a piece of wood. Treatment is accomplished by placing wood in a large chamber, filling it with liquid solutions, and pressurizing the chamber once the lumber is saturated. As a result, the chemicals will prevent or block the wood fibers from becoming a food source for termites and fungal decay: It's that simple.

What is not simple is understanding how these chemical-based solutions protect the wood. A preventive based chemical treatment simply exists within the lumber and a blocker adheres to the wood fibers within the lumber. Understand, a preventive based solution only works so long as it remains within the lumber.

The problem in Central Florida is pressure-treated wood fences are constantly assaulted by groundwater, rainfall, and irrigation systems. Like a sponge, the wood absorbs the water and the lumber swells. Unlike a sponge, that lumber cannot be wrung out. The abundance of water slowly forces the very chemicals meant to protect the wood out of it, leading to chemical leaching. A blocker-based treatment, on the other hand, allows the compounds of the chemical to stick to the wood fibers resulting in better retention. Simply put, the treatment lasts longer.

Preventive-based treatments such as MCA and E2 were the treatment of choice for all outdoor lumber from 2007 to 2011. It did not matter if the end-use was above or below ground. In 2009, the makers of the chemical MCA started to realize lumber placed below or in contact with the ground was rotting. E2, on the other hand, possessed wood polymers and stabilizers whose sole function was to delay water absorbing for 1-3 years. In 2011, the pressure-treating industry realized there was a systemic problem. Bottom line, both MCA and E2 treated lumbers was rotting when within 6" of the ground.

So began the race to find the cure for fungal decay and rotting at ground level. The two major chemical producers of chemical-based treated solutions, Viance and Osmosis, created two different new treatment code Copper Azole Type C (CA-C) and MCA-C. Then began the battle for control of the American Wood Protection Association (AWPA) classification codes and standards. Both companies slugged it out. Both approaches were not created equal. To avoid market confusion, the AWPA introduced three new end-use categories for pressure-treating lumber in their 2016 standards: UC4A, UC4B, and UC4C.

The AWPA was based on the fact that lumber is treated for a particular end-use application with different chemicals. Now, depending on the end-use, the retention percentage of the chemical-based solution within the lumber determined how effective the chemical would be given in a certain condition. Case in point, the category UC4a is meant for ground contact (general use), within an environment that promotes rapid watershed were as UC4B is meant for ground contact (heavy duty) within an environment that possesses slow watershed. Finally, UC4C is meant for ground contact (extreme duty) within an environment consisting of stagnating water.

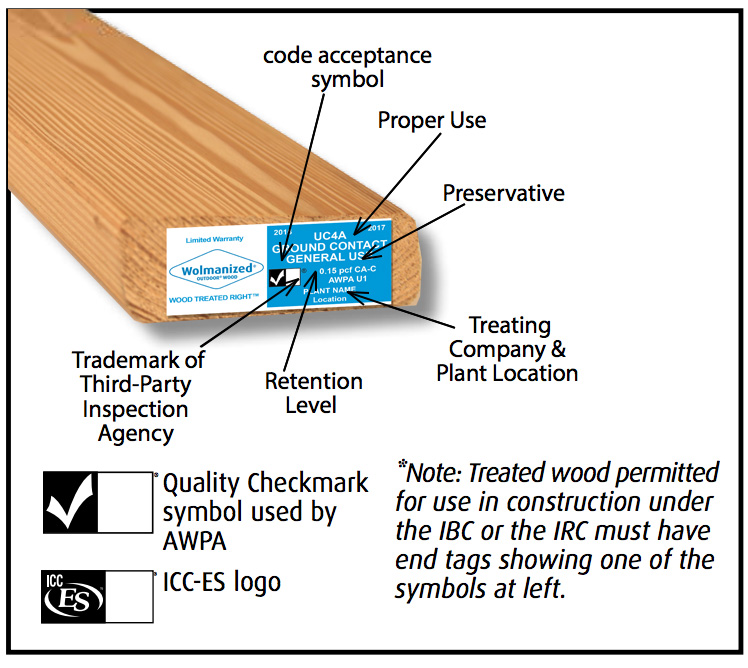

As you can see, knowing is half the battle. So the question is, how do you know you're purchasing the right pressure-treated lumber or is that fence company installing the correct stuff? Look no further than the tag stapled to the piece of lumber. If you need further explanation or a better understanding of what category and chemical are right for each building situation, print off the AWPA's pamphlet. As the old saying goes, "Trust but Verify." Take it with you to the home improvement store or better yet take a tag off the lumber being used to install your fence.

We cannot stress this enough: It is now more important than ever to understand the intricacies of pressure-treated lumber and the manner in which your wood fence is constructed. None of our competitors will share this information with you, and some will say, "We are crazy." But just look around your neighborhood and chances are you will see rotting pickets and posts hard at work.

FACTOR THREE: BUILDING METHODS

There are two basic methods of fence construction. They are prefabrication and onsite building/stick building. Both methods require that a post be installed every eight feet. No exception. In addition, each method will vary depending on the fence company, but the basics will hold true. We have added our method of construction to provide a contrast and to explain why we build to such a strict standard. Below are the basic definitions of each building methods, the availability, aesthetics, and anticipated longevity:

PREFABRICATED FENCING: This building method consists of prefabricated eight foot sections of fence. These sections are often purchased by fence companies and homeowners at the big box stores and discount outlets. They are pre-built using 2" x 3" x 8' rough cut runners, 1/4" x 4" x 6' rough cut dog-eared pickets. All pickets are attached to the runner with a small tack-nail or staple.

At the point of installation, an 4" x 4" x 8’ rough cut line posts is installed every eight feet. The section is placed on the post, and the runners are secured with (1) 3" Galvanized penny nail. Finally a picket is added to cover the seams.

The majority of Central Florida fence companies use this method of building. Why? The answer is simple: The materials are cheaper, the skill set needed for installation is minimal, and the method is highly profitable.

When it come to aesthetics and structures, this building method receives a thumbs down! Understand, the aesthetics will fade within 6 month; and the fence itself will only last 4 to 6 years.

PREFABRICATED FENCING IS HIGHLY SUSCEPTIBLE TO THE THREE DISTINCT PROBLEMS, AND WE DON'T RECOMMEND IT OR INSTALL PREFABRICATED FENCES.

ONSITE/STICK BUILDING: This method of building requires the fence to be constructed piece by piece using 4" x 4" x 8' rough cut line posts, 2" x 4" x 8' number 2 primed runners, and 1/2" thick rough cut dog eared pickets.

A small percentage of Central Florida fence companies use this method of building; however, more and more onsite builders are popping up in the marketplace. As a result, these newer builders make simple mistakes but ones that cost the homeowner dearly. Mistakes such as using the wrong picket spacing, the wrong nails, or the wrong lumber. Make sure the right questions are asked.

When it comes to aesthetics and structures, this building method receives a hesitant thumbs up! If it's not built correctly or someone cuts a corner, this building method is just as dangerous as prefabricating. Understand, if build correctly, the aesthetic will last 3-5 years; and the fence itself will last 8-10 years.

THIS METHOD IS MORE RESISTANT TO THE THREE DISTINCT PROBLEMS IF BUILT CORRECTLY. SEE PRO'S AND CON'S.

PARAMOUNT 'S REINFORCED METHOD OF ONSITE/STICK BUILDING: It all starts with the framework. Our method requires the fence is assemble piece by piece using 4" x 4" x 10' number 2 primed line posts, 2" x 4" x 16' number 2 primed horizontal runners, and 1" x 6" x 6' rough cut pickets. To ensure all lumber remain secure, we use a serious of special treated nickel-alloyed, yellow tip, ACQ rated, ring-shank nails: A ring-shank nail has 50 reversed ovular rings which acts like threads on a screw when it punctures the wood.

At the point of installation, 4" x 4" x 10' number 2 primed line posts are installed every eight feet. Then the (3) 16' horizontal runners are staggered and secured to the post using (2) 3" nickel-alloyed, yellow tip, ACQ rated ring-shank nails per runner. Each picket is then individually secure with (6) 2" nickel-alloyed, yellow tip, ACQ rated-ring shank nails.

Only one percent of Florida Fence Companies build to our standard. WHY? The answer is simple: The material requirements cost more, the skills needed for installation are greater, and the profit margin is low. It is just a fair exchange between homeowners and companies which promotes long term growth.

Our method of building can last approximately 12 to 15 years in both splendor and longevity. It just depends on how well the individual homeowner takes care of the fence. We give it two thumbs up!!

OUR METHOD OF BUILDING IS RESISTANT TO THE THREE DISTINCT PROBLEMS! HOW YOU TAKE CARE OF IT WILL ELIMINATE THEM!

FACTOR FOUR: PRO'S AND CON'S OF EACH METHOD

Each building methods possesses different pros and cons. Often, the benefits and downfalls of a building method rest upon the materials used. Understanding the specific types of lumber, and how the specific types of lumber effect each building method will prevent simple mistakes.

PREFAB FENCING: ALL CON'S HERE

If you are still considering prefabrication, stop. Understand the CONS and move on....

Runners Size: (CON) Considering most prefabricated panels are constructed with 2" x 3" x 8' rough cut runners, which are milled from small sapling trees or the outer parts of large trees, the lumber itself is vary porous. Not only is it porous, the pores are large and low in numbers. Translation: they are more susceptible to fungi and water damage.

At the end of the day, the 2" x 3" x 8' runners will cup and bow at the slightest hint of moisture. The combination of the preservative and the tropical weather will force the lumber through a mini-recurring process each time it gets wet. As a result, the aesthetics and structural integrity will be nonexistent within two to three years. The key thing to remember here is that the thinner the lumber is, the more it will be susceptible to the three distinct problems.

Post depth: (CON) A prefabricated fence panel forces the 4" x 4" x 8' rough cut line post too far out of the ground. As a result, the line post is set less than 27" deep. The basic issue here is leverage.

At a minimum, the depth of the posts should be determined by the height of the fence being installed. For example, a six foot in height fence should be supported by posts set 24" beneath the surface. As a result, a leverage ratio of 6:2 is created.

In a perfect world the minimum works; however, this is Florida. Our soil content is mostly sugar sand, and each post will naturally lose on average 5" to 8" inches of leverage. As a result, most prefabricators use concrete to achieve minimal leverage.

Beware, concrete and the pressure treating preservative do not get along. Concrete causes posts to stay moist which creates the perfect breeding ground for wood rot, mildew, and termites. Not to mention, the moisture will cause the posts to twist, to split, or to bow like a banana.

The fasteners: (CON) A prefabricated fence panel requires the use of some type of small staple or galvanized tack nail. Otherwise, the staple or tack nail would split the thin porous lumber.

Prefabricated Fence Panels

Stick-Built-On-Site Fence

Understand, small tack nails and staples are manufactured from hard and heavier metal elements. As a result, the small fasteners are manufactured in galvanized formed and then coated with a protective barrier.

Beware, the new pressure treating code has a high copper content and will eat through the protective barrier ins six months, and rust-out the galvanized nail within a year.

The pickets: (CON) Prefabricated fence panels are traditionally built with rough-cut pickets that are less than a half inch thick. Thinner pickets are used because thicker pickets would increase the weight making them too heavy to install.

The problem with thinner pickets is the lumber from which they are milled. Just like the runners, the pickets are milled out of small saplings or the outer edge of large trees. This may not sound like a concern, but the ground exposure will rot and decay them quickly. The thicker the picket, the less susceptible they are to wood rot.

Understand, it does not matter the type of wood: pine, cypress, or western red cedar. These types of lumber are resistant from rot when they are milled from large trees and pressure treated. All the before mentioned woods are dependent on the long-term growth of 40 plus years. After 40 years, the rings get tighter; and the closer the rings are, the more the pores are closed. The covenant dark colored heartwood does not develop in most species for 70 years.

Rough cut lumber is harvested when trees have reached between 20 and 40 years old.

ONSITE/STICK BUILDING: If done correctly, onsite building is a better approach. If done incorrectly, onsite building can be a disaster!

Runners Size: (PRO) Most 2" x 4" x 8' runner; milled out of large mature trees and cutout from the core. As a result, the 2" x 4" is called prime lumber, its milling grade is 2.

The advantage of the 2" x 4" x 8' number 2 prime lumber is the lumber itself is less porous. There are three factors that provide the advantage of rough-cut lumber. First, large trees have tight rings. Second, the tighter the rings, the lower the pore count. Third, the milling method assists in closing the pores. When combined, all three factors make the lumber less susceptible to water and fungi damage.

The disadvantage of the 2" x 4" x 8' is all about installation. If the crown of the 2" x 4" is place in the wrong direction, the board will cup and bow. If the posts are not spaced correctly, the 2" x 4" will twist and separate from the post.

Keep in mind, 2" x 4" creates three open seams at every post. In return, the three seams create a weak point, and seams are dependent of the depth of a posts. If the posts used are too short, they will move. When they do, the three seams will separate, and the integrity of the structure will be compromised.

Post depth: (CON) Because most onsite/stick-built fence builders still use 4" x 4" x 8' rough cut line post, we must rate the standard method of building a con.

Understand, the standard method of building forces the 4" x 4" x 8' too far out of the ground. In most cases, the post is less than 27" in the ground once installed. Considering Florida soil is based on sugar sand, the posts will lose on average 7" of leverage.

To provide adequate leverage, concrete is often necessary. However, that is not always the case. Most onsite/stick-builders will not use concrete.

Regardless, concrete, when combined with the new pressure treating code, causes posts to warp, to rot, or to bow.

The fasteners: (PRO and CON) Onsite/stick-built fences are built with thicker lumber than prefabricated panels. As a result, the lumber requires thicker and softer metal nails to hold it in place.

WARNING: All fasteners must be nickel or chromium alloy-based ring shank nails, not standard galvanized nails. Use the wrong nail and your fence will be a complete loss.

Should a builder use standard galvanized nails, the fence will have the same issue as a prefab. All the nails will rust out and the pickets will pop within a year or two.

The pickets: Onsite/Stick-built fences are generally built with a thicker picket. Most are 5/8" or thicker. The problem once again is the lumber from which the pickets are created. Understand, all pickets are considered rough-cut lumber. As a result, the pickets are more porous then the number 2 prime lumber, however, the thicker the lumber the tighter the pores. The tighter the pores the more resistant it will be towards rot and decay.

Remember, it does not matter what type of wood the pickets are cut from: pine, cypress, and western red cedar. These type woods are dependent on the long-term growth of 70 plus years to develop heartwood. Rough cut lumber is harvested from tree farms.

WARNING: The size of the picket is a nominal measurement. For example, a 1" x 6" x 6' dog-eared picket is not the actual board measurement. When a picket is milled, the final thickness is actually 3/4" x 5 3/4" x 5 3/4'. It doesn’t stop there. Understand, by the time picket is purchased, the new pressure treating code causes the picket shrink. As a result, the picket has shrunk to somewhere around 5/8" x 5 1/2" x 5 5/8'. Once the picket cures, the final measurement will be around 3/8" x 5 1/2" x 5 1/2.

Don't let the label fool you.

Horizontal Streamline Fence Assembled On-Site By Paramount Fencing

PARAMOUNT'S REINFORCED METHOD OF ONSITE/STICK BUILDING: This is the best approach to building a wood fence under the new ACQ pressure treating code.

The Runners: (PRO) Unlike the standard method of onsite building, we use 2" x 4" x 16' number 2 primed lumber. We still install a post every eight feet, but we stagger runners between. Our method of staggering longer runners, coupled with the longer posts, creates a long-lasting framework. In addition, due to the length of the runners, the lumber is milled from the heart of large and mature trees. The pores are tight and small, or often closed. As a result, warping and cupping are minimized and crown direction does not matter.

Post depth: (PRO). Unlike the traditional 4" x 4" x 8' rough cut line post, the 4" x 4" x 10' number 2 prime line post rests 48" beneath the surface. As a result, adequate leverage is provided to the structure as a whole: six feet above and four feet below equals a 60% leverage ratio above ground. When the posts are coupled with longer runners, both set the stage for a solid wooden wall. As a result, there is no need for need for concrete and it counter the three distinct problems with the pressure treating code.

The keys component of the 4" x 4" x 10' number 2 prime line posts are the length of the post, lumber, and the milling. Things such as tighter rings, closed pores, pressure treated lumber for below ground contact, and a 40% saturation ratio.

The pickets: (PRO and CON) We use a variation of 5/8 and 1" rough cut pickets. It depends on style and budget. There is no real alternative such as a Number 2 prime picket; however, the following principle can be applied: the thicker the picket the tighter the pores. The tighter the pores, the more resistance it will have towards rot and decay.

Remember, it does not matter the wood type. Pine, cypress, and western red cedar only work when they are milled from large mature trees. These types of woods are weather resistant, but are dependent on the long-term growth of a tree. Most species require 70 plus years to develop heartwood: a dark dense area of tight rings. Most rough-cut lumber is harvested from tree farms before 30 years.

A SPECIAL NOTE: There are no distinct advantages to using cypress pickets unless you use number 1 grade kiln-dried cypress post as well. Most companies using cypress pickets must resort to pressure treated pine framework because kiln dry framework (posts and runner) is too expensive. They could use a green cypress; however, it would have to be pressure treated. Bottom line, cypress pickets do last a few years longer than pine pickets, but what good will it be if the framework is rotted and on the ground? It's all about the framework.

UNDERSTANDING THE BUSINESS MODELS THAT DOMINATE THE CENTRAL FLORIDA FENCE INDUSTRY

You must understand the importance of asking the right questions. Most fence companies located in the Central Florida area are not major corporations, are not publicly traded, or bound by state ethics or a regulatory board. If there is a problem, you have no recourse.

Understand all you need is a tax receipt from your local municipality, and anyone can start a fence company. The tax receipt is generally under a hundred dollars and issued over the counter. Think twice about who you call because that person knocking on your door could be the butcher, the baker, or the candlestick maker.

The other thing to consider is the economy and the effects on fence companies. Prior to 2006, there were hundreds of legitimate fence companies in the Central Florida Area.

There are many general types of business models fence companies operated within the Central Florida Area. We have named them accordantly with title such as Back Yard Bargain Joe, The Discounter, The Traditional Company, and The Educator. Each business model is distinctly different. Each will offer a different combination of building methods and level of services. It's important to understand who you're dealing with at all times. Most importantly, you'll get a pulse on the character of the company.

1. Backyard Bargain Joe: These type of fence companies dominate the Central Florida market. They are usually a one-man operation whose main focus is based on delivering the cheapest possible products and method of installation. Understand, this business model is often flooded with certain types of individuals:

- New startups: An individual who has started the process of delivery fence and service to the marketplace. They often meet the state and local licensing requirements but lacks appropriate insurances. Use at your own judgment.

- Fly-by-nights: Individuals that participate in the fence market during a hurricane or time of need. They do not meet state or local licensing requirements or insurance requirements. Never use.

- Handymen: These individuals are the jack of all trades, but masters of none. They often meet the county requirement for handyman, but not for fencing. Never use for fencing.

- Independent contractors: These individuals have worked for a traditional fence company. They are often former employees or contractors. Special attention must be paid to the word "Former." Understand, the downward economic trend has forced fence companies to layoff or fire installers. As a result, they have flooded the market. Most meet state and local licensing requirements; however, most do not carry the appropriate insurance. Use at your own judgment.

- A friend of a friend just trying to make a buck: these individuals have often installed a few fences for a friend or a family member. They rarely possess any form of licensing or insurance.

- The conman: We would like to identify them, but they are ever changing. They rarely have state or local licenses. Our best advice is to trust but verify. Understand, how they operate: they tell their victims exactly what they want to hear, they change what they say, and spend a lot of time talking about themselves.

Understand customer service is poor or none-existent within these models. If there's problem, it's rare for it to be resolved. As a result, these companies and individuals are short lived within the market but often at the homeowner’s expense.

Quality of product is poor. The main building method is prefabricated fence panels. It is rare to find the onsite/stick building method at work in this model.

The business model pledged with cash flow problems. As a result, it requires the customer to surrender a deposit of half or greater. Once the money is received, the wait for installation is often lengthy. Chances are the homeowner will end up hounding the individual or company to actually get the fence installed. When fence is installed, it's often wrong or riddled with issues and poor craftsmanship. Understand this model accounts for 20% of all fence installed in the Central Florida market.

This model is ultimately flawed, but easily identified. There are always three dead giveaways:

1. The individual spends more time selling themselves than the product, the company, or services they offer.

2. Little attention is given to the details discussed, and those details are rarely written down in a true proposal format. Instead they are scribbled out on generic carbon copy estimate paper and are written with ambiguous and general terms.

3. The proposed price is rock bottom low.

The Fence Discounters: Buy it cheap and maximize profit through volume. Believe it or not, this model is ran by 5% of the local fence companies; however, this model accounts for 40% of all fences installed in Central Florida. Their primarily focus is on economy grade fencing, but do carry a small lines of premium grade products. Why one might ask? The answer is simple. It's the retail philosophy: Carry a high price product, and the cheaper product will be more attractive. Each time the customer will focus on price and not quality or longevity of a product.

The problem with the fence discounter is they often have their hand in every aspect of the market. The sale fence directly to the public, they offer some form of installation, and at the same time wholesale to all business models.

- Big Box Stores: Any major retail store that sells home improvement products.

- Outlets: Retail locations sell strictly fence related products to the public.

- Large Regional and National Fence Companies: Established fence companies that have office locations regional and nationally. Their main focus is selling to other fence companies.

They bank on the do-it-yourselfers. A customer show up to a retail location, purchases material, and then it's delivered. To keep it simple, The Fence Discounter sells prefabricated fencing systems and requires a large deposit.

It’s hard to separate fact from fiction with The Fence Discounter. Product lines and services often get blurred. They often tell a customer what they want to hear, and little emphasis is placed on education or quality of product. Instead, they often explain the advantage of premium fence but understand their solo purpose is to push economy fencing systems. For example, a customer inquires about fencing, and the representative explains the advantages of the premium fence. He gives the consumer the price. The consumer is shock, but the representative says, "Well, we have this less expensive option." Hence the consumer swallows the bait: price over quality.

If the discounter offers fence installation, the installation of the fence is often poor to adequate. Remember, The Fence Discounters goal is to buy it low and sell in volume to make their profit. As a result, the individual installing the fence is forced to work faster, longer, and harder to make a living. As a result, there is a high turnover rate in their installation department.

This model is flawed, but it works. The problem is it ultimately burns the consumer. Remember, if you try to save a penny, you will spend a dollar to fix it. There are always three dead giveaways:

A. The individual spends more time selling themselves then the product, the company, or services they offer.

B. Little attention is given to the details discussed. It’s all about what you want and when you want it at the lowest possible price. Details are written down in a proposal format; however, it is written with ambiguous and general terms.

C. Their advertisements often contain statements such as “we will beat our competitors’ price, or we'll do it for less.” They advertise large discounts and gimmicks.

Understand, a discounter possesses some level of customer service. It is a take it or leave it approach to solving problems. For example: If there is a problem, The Fence Discounter will fix it, but the solution will be based on minimizing losses. As a result, the customer often suffers and must accept the offered solutions.

3. The Traditional Fence Company: They are around for the long haul. They will offer products and services that leave customers generally satisfied. If there is a problem with the products or the services, they will fix it. The solutions proved will not be based on minimizing losses, but by doing just enough. The reputations of a traditional fence company generally matter to the owner; however, it really depends on the owner. Who are they:

A. Business-people: Individuals that see a need and fill it.

B. Professional good at their craft: Individuals that have a passion for building.

C. Families: Companies that are past down from generation to generation.

The traditional fence company makes it money on satisfied customers but understand traditional fence companies are also all about the numbers. The operate on the principle of laws of average. For example, if "X" number of estimates are ran, "X" number of jobs will be sold. Run enough estimates and the work will be plentiful. Treat enough customers right and the reputation will assist in obtaining new business.

Do not be fooled. It is a dog eat dog business model in today's market, and all of them are scrambling for only 35% of the Central Florida market. All traditional Fence Companies are not created equal. Some will pride themselves on service. Other will pride themselves on fence installation, and a few will pride themselves on products. It's rare to find all three running hand in hand. Even in that case, their pride will depend on what they consider their competitive advantages. This is a great model, but understand problems still exist.

Problems often starts at the estimate level. Like most industries, the sales and estimating position possess a high turnover rates. The owner is then forced to constantly train new salespeople. The information needed to provided outstanding serves, products, and customer service, comes and goes with the estimator. As a result, the primary focus of a fence company is sales. Once a salesperson is trained, they’re sent off to visit a property and promise things they barely understand. For example, a company might carry a great product but have poor installation results. This is often caused by hiring and firing employees based on workflow. As a result, the experience comes and goes.

Because so much time is spent on training estimators, the little details are often missed or sacrificed on the backend. Simple things like communicating with the customer once the contract is signed. Maybe it’s calling in the underground utilities, pulling a permit, or double checking the scope of the project. Regardless, something is often sacrificed. Most of time it’s because of a short-lived position in the company. When it comes to the morning of the fence installation and the installer knock on the door and asks the customer where the fence goes, that’s often when a customer realizes that the customer service wasn’t the company’s strong suit. When the job is complete, the customer is often left saying, "I like it, but…" In the end, the customer is forced to settle.

4. The Educator and Perfection Fence Company: This model focuses on the long-term growth over short-term gains. Strict focus is placed on educating and gaining satisfied customers.

These companies are often at the top of their industries and are reputation driven. As a result, it is not necessary for these types companies to dump tens of thousands into advertising, which allows them to use that money to increase the quality of their products and services. Should a problem occur, this type of company will not need to be told how to do the right thing.

The Good news is Paramount Fencing is an educator and perfection fence company.

You'll never know what someone is offering unless you ask the right questions.

Below are a few questions you should ask:

What type of wood are they using?

Pressure Treated Southern Pine is the best for our climate. Cypress is available, but most of it comes from up north and might be more costly. Additionally, the cypress of today is not the cypress of yesterday. Don't be fooled.

Avoid wood from other countries. Some home improvement stores purchase their wood from distributors whom import. If it's not tag from a local distributor such as Top Choice, Universal Forest product, Yellow wood, or Eco Life, Max Life you probably don't want it.

Avoid wood mixed with plastic. If you want long lasting fence, Vinyl will always look better, be low maintenance, and cost the same or less.

Avoid prefab fence panels at all cost. Just take a drive around your area and look at the prefab fencing replaced since the hurricanes. You will notice pickets pulling away, excessive warping, splitting, cracking and cupping. If someone tells you, it's built on site, but the sections are assembled at the shop, it still a prefab, run.

What type of nails are they using?

EXGV Double galvanized yellow tip ring shank nails or nickel alloyed ring shank nails, All .113 shaft. Stainless steel ring shanks are the best, but are more expensive

The number one mess that we clean up is the use of regular galvanized nails or staples. Understand that with the new pressure treating codes, standard galvanized nails decay 10 times faster. Additionally, wood likes to move around, and if you don't give it a reason to stay in place, it won't.

Avoid staples and small single coated nails because they will rust quickly.

What is the thickness of the wood being used?

When it comes to pickets, anything under 5/8" thick is not good.

Avoid 2" x 3" x 8’ runners because they sag, bow, arch, and do not provide enough horizontal support.

All gate posts need to be 4" x 6" x 10' at a minimum to prevent sagging of gates. This is the number one area people generally experience problems.

All fence posts need to be 4" x 4" x 10' and avoid the 3" x 3" x 8' round landscape timbers. It may not seem cost effective at first, but as the old saying goes; try to save a penny, plan to spend a buck to fix it.

How many runners do they use? Do they attach the runners to the post or go between posts?

Avoid companies that use two runners. BAD, BAD, BAD!

Avoid companies that go between posts because the fence will fall apart. It's Florida, not Georgia or up north.

Most companies building between the posts will not take the time to either route the posts or use the correct fasteners. Couple this with the fact that pressure treated lumber shrinks, you could have a mess on your hands. They try to use brackets to nail directly into the posts.

The best is attaching the runners to the inside or outside of the posts using ring shank nails, which will secure them flat to the surface of the post or rout the posts.

Ask how many pickets are used to cover an 8-foot stretch of fence?

It should be 24 for board on board, 17 for stockade, and 24 for shadowbox. Any less is not good because pressure treated lumber shrinks. For example, 1" x 6" x 6' shrinks to 3/4" x 5 1/2" x 5 5/8' and if someone is using less, that means they are stretching out the picket. When the pickets shrink, noticeable gaps will develop.

If you are using a cypress picket or specially milled lumber, the picket count per eight-foot section will be less. What’s important is that you watch the overlap of each edge of the picket. You want a minimum overlap of one inch on each side. Anything less is a disaster.

Do they pay their people by the hour or by the foot?

Avoid companies that pay by the hour. Nine times out of ten, the crews installing have a limited skill set and a high turnover rate. The installers are paid equivalent to fast food workers, and you will get what you pay for...

Avoid companies that use illegal workers or have an out of state license or provide workers who cannot communicate.

Companies that pay by the foot generally keep the best workers in Central Florida.

How long have they been in business?

As the old saying goes, trust but verify. The following link will take you to the state of Florida business website where you can find a page full of links which will let you research the company: http://www.sunbiz.org/search.html

If you just want to look up the company and see if they are a valid company, use the following link and type in the name of the company: http://search.sunbiz.org/Inquiry/CorporationSearch/ByName You will either find the companies name or you will discover their status. If the status of the Corporation is active, that’s good. If the status is inactive, you need to send that company packing. You will have no recourse if something goes wrong.

Are they members of any organizations such as the BBB or Angieslist?

Next research them through the BBB or referral sites.

If you want to be creative, type in the following key terms into the google search engine: I hate (name of company).

Preservation of fence: Regardless of which assembly method used, the preservation of the fence will make all the difference. Most damage to wood fencing occurs in the first six months to a year. The culprit is the afternoon thunder storms. Something as simple as an acrylic or oil-based water sealant can make all of the difference.

Acrylic Based: Anything is better than nothing. The downfall to acrylic based water sealant is it needs to be done annually. It can leave a pasty look and result in time consuming maintenance to restore the original beauty.

Oil Based: The best thing for your fence. Oil-based protection seeps to the center of the wood and dries from the inside out. As a result, the maintenance schedule is simpler and further apart.

Final Note: Avoid any company requesting that the homeowner pull the permit. If this is the case, the company may not have the correct insurance needed to conduct work within the municipality. Additionally, if a homeowner pulls the permit, they assume all the liabilities for one year. Lastly, make sure all your underground utilities have been located or it could be an awfully expensive fence. Most fence companies have this capability and the service is free of charge.

Board-on-Board Fence Stick-Built by Paramount Fencing

TO SCHEDULE A FREE ESTIMATE CALL! (407) 341-2720 Family Owned & Operated Since 2003 Veteran Owned and Operated.